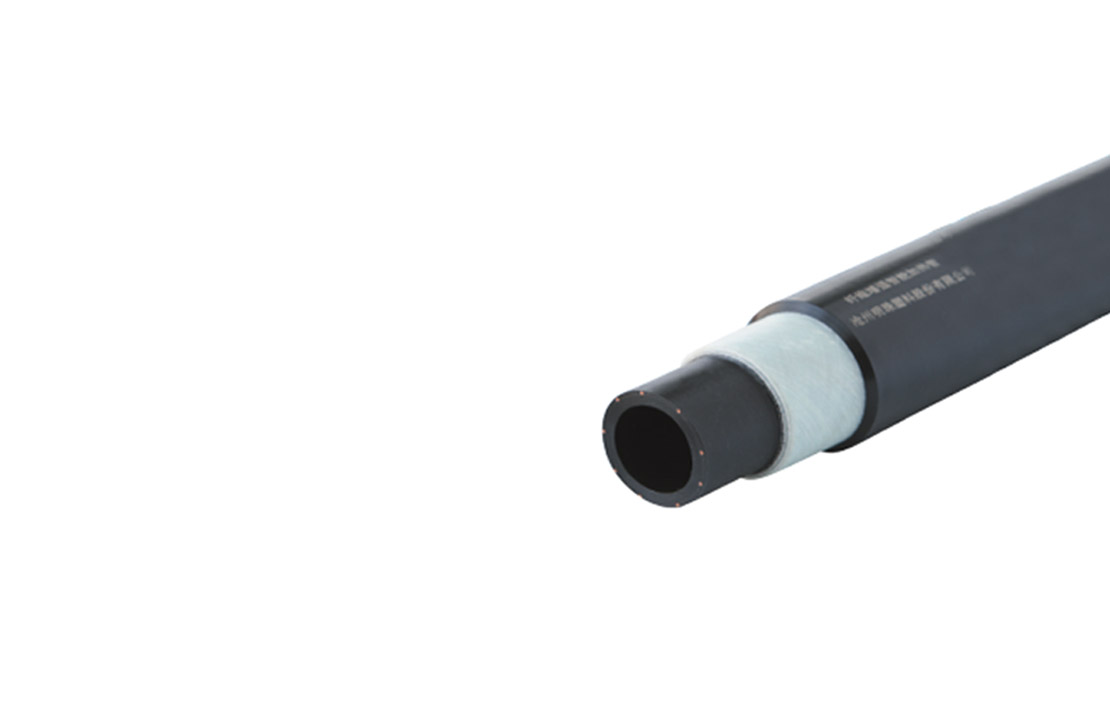

It has obviously advantage such as high strength, corrosion resistance, light weight, low surface friction coefficient, good flexibility, long service life, and good customization, as well as easily construction and intelligence, low accident rate.

High strength: the burst pressure over 120MPa, the collaspe over 30MPa, and the tensile broken force over 400KNs and the higher specification can be designed according to the requirement;

Corrosion resistance: It can bear strong acids and alkalis, suitable for various corrosive environments, especially fluid containing H2S and CO2;

Temperature resistance and heat isolation: The long term operating temperature is ≥85°C, and the comprehensive thermal conductivity coefficient is 0.42W/(m·K), which can reduce the thickness of the insulation layer or even without the insulation layer;

Light weight: It is only half of the steel pipe weight at the same diameter and pressure level;

Low surface friction coefficient: The equivalent roughness is only 0.0015mm , not easy to form scale or wax, 16% higher than the steel pipe flow at the same diameter, and the smooth inner surface can save power consumption;

Good flexibility: The pipe elastic deformation range is 3% , which can compensate the stress caused by pressure and temperature. It can be repeated coiling and de-coiling, and has good adaptability to different condition ;

Long service life: The pipes have passed the 10,000-hours long-term hydrostatic test according to ASTM D2992, and the service life is at least 20 years.

Good customization: Customers can provide the requirement and we design the customersized product, such as heating pipes, anti-wax pipes, anti-scale pipes to improve the transportation efficiency and lower the maintenance cost;

Easily construction: The maximum length of a single pipe is over 2,000 meters, the continous pipe is easily to construction;

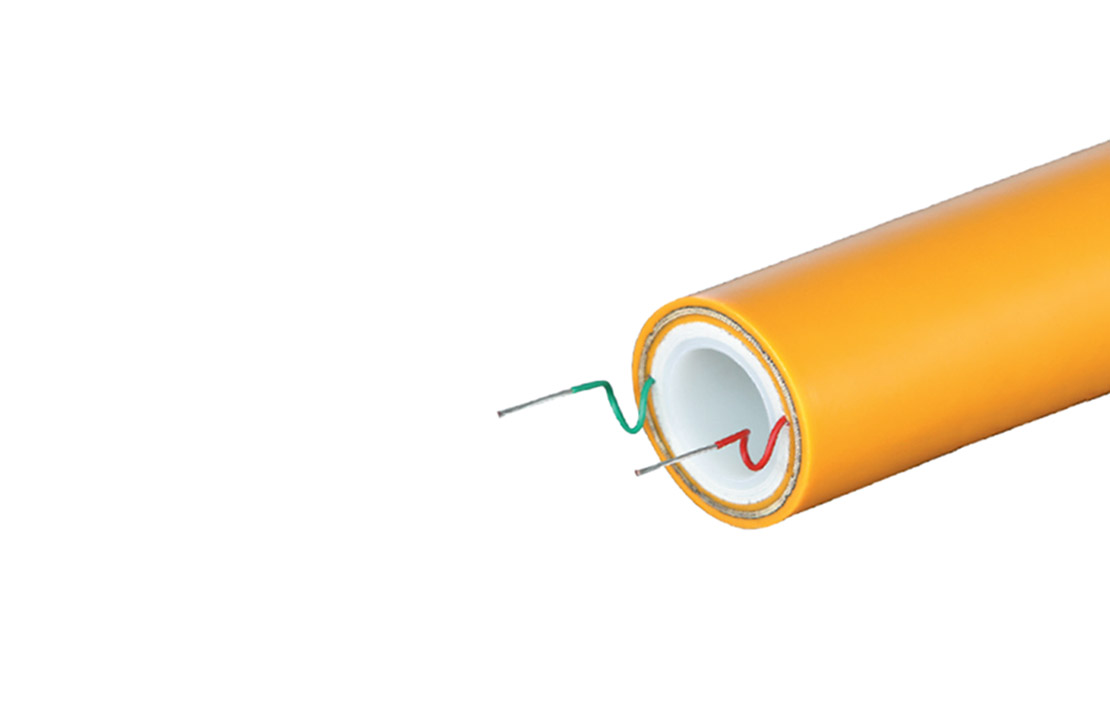

Intelligence: The embedded signal cables and sensors or optical fibers can transfer data to the management personal in real time through the communication module, making it possible to control parameters of the downhole liquid level, temperature and submersible pump at any time, and use the mega data platform combined with the internet to construction the smart oilfield;

Low accident rate: Cables, optical fibers and other sensing units are embedded in the pipes, and the pipe lift and down can be finished within one day by using special operation equipment , which greatly improves operational efficiency while reducing cable collisions, cable abrasion and other accidents.

Cable-Embedded Production Coiled Pipes

|

Maximum Working Pressure (Mpa) |

15 |

20 |

||

|

Long-term Working Temperature (°C) |

≤85 |

≤90 |

≤130 |

|

|

Diameter (mm) |

≥35 |

≥40 |

||

|

Outside Diameter (mm) |

≤80 |

≤90 |

||

|

Weight (kg/m) |

约4.77 |

约5.45 |

||

|

Minimum Bend Diameter (m) |

0.95 |

1.05 |

||

|

Axial Tensile Force (kN) |

≥250 |

≥300 |

||

|

Delivery Power of Power Supply (kW) |

10~20 |

|||

|

Power Supply (V) |

380±20 |

|||

Cable-Embedded Water Injection Coiled Pipes

|

Maximum Working Pressure (Mpa) |

25 |

35 |

|

Long-term Working Temperature (°C) |

≤85 |

|

|

内 径(mm) |

≥50 |

|

|

Outside Diameter (mm) |

≤80 |

≤90 |

|

Weight (kg/m) |

约4.4 |

约5.0 |

|

Minimum Bend Diameter (m) |

1.0 |

1.2 |

|

Axial Tensile Force (kN) |

≥250 |

≥300 |

Cable-Embedded Water Injection Coiled Pipes

|

内 径(mm) |

40~80 |

|

Maximum Working Pressure (Mpa) |

32 |

|

Long-term Working Temperature (°C) |

≤85 |

|

Heating power (w / M) |

0~60 |

|

Heating efficiency |

60~80% |

|

Power Supply (V) |

380±20V |

|

每公里温降(裸管) |

约3℃ |

|

每公里温降(20mm保温层) |

<1℃ |

内嵌缆采水连续管

|

内 径(mm) |

≥50 |

|

Outside Diameter (mm) |

≤100 |

|

Maximum Working Pressure (Mpa) |

16 |

|

Long-term Working Temperature (°C) |

≤85 |

|

Load Power (kW) |

≥30 |

|

Water Extraction (m3/Day) |

200~400 |

|

Power Supply (V) |

380±20 |

|

Axial Tensile Force (kN) |

≥120 |

|

Temperature Drop Per Kilometer (20mm insulation layer) |

<1℃ |

.png)